Research Projects Conducted by GWE:

Thermo Chemical Energy Storage

Thermo Chemical Energy Storage

This project seeks to integrate a novel solar absorber architecture and a thermochemical storage system, based on coupled metal hydride materials, in a single close-coupled system, integrated in a super-critical CO2 power plant. The working fluid absorbs incoming solar energy and donates some fraction of it back into the thermal energy storage system for use during off-sun operation. The high energy density of the storage system allows it to be mounted up-tower alongside the receiver, which further enables up-tower mounting of the entire sCO2. Brayton power block. The integrated solar power system will achieve high solar to electricity efficiencies with projected electricity costs lower than 6 c$/kWh.

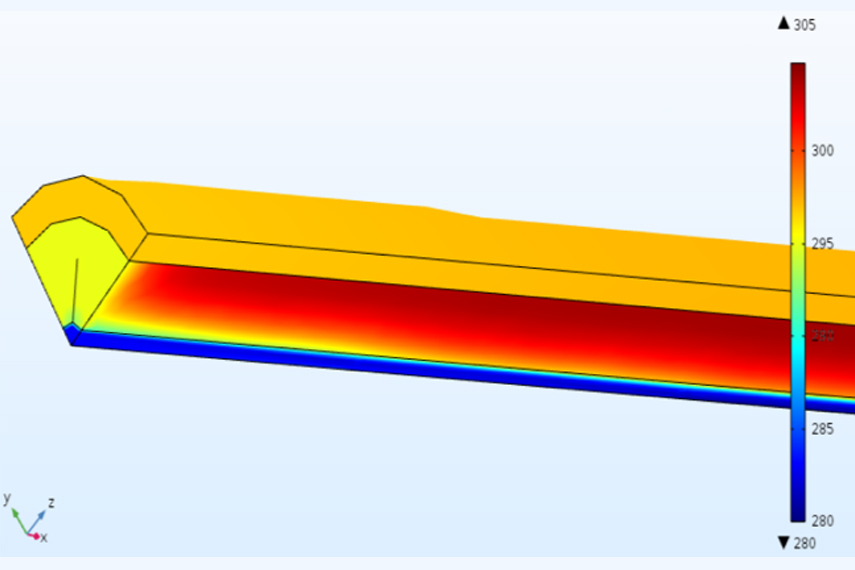

EC/MH Compressor

EC/MH Compressor

This project proposes to combine two technologies, Electrochemical Hydrogen Compression and Thermal (Metal Hydride) Compression into a new hybrid hydrogen compressor. The goal is to evaluate the hybrid system for hydrogen refueling and other potential commercial hydrogen applications. Techno-economic and detailed three dimensional modeling of the system, as well as experimental activities, will be carried out to evaluate the performance of the proposed hybrid compressor against the US Department of Energy targets. A prototype hybrid unit will be designed and fabricated at Greenway Energy laboratories, achieving hydrogen flow rates of 1-5 kg/day and outlet pressures of 875 bar.

Catalyst Support

Catalyst Support

This project addresses technical targets from the US Department of Energy’s Fuel Cell Technology Office-Multi-Year R&D Plan to enable commercialization of fuel cell electric vehicles by improving the performance and durability, while reducing the cost, of catalyst supports within polymer electrolyte membrane fuel cells.

Demonstration of corrosion resistant carbon support stability in the presence of Pt and Pt-alloy nanoparticles under 1.0-1.5 V potential cycling condition will be carried out to meet the US Department of Energy technical targets for catalyst support.

Metal Hydride Material Development

Metal Hydride Material Development

This project aims to establish a materials-genome based high-throughput technique to define and develop a new class of metal hydride materials for high pressure hydrogen compression, achieving reduced costs and high efficiencies. Specific material properties, required to meet the Department of Energy targets for hydrogen compression systems, will be identified. After validation of the high throughput methodology by comparing the results with the available material data, the technique will be applied to identify new material formulations that meet the targets. The new material will be fully characterized at bulk level in terms of thermodynamic, physical and kinetics properties and cycling performance. A new compression system will also be designed based on the new material, coupled with an effective heat transfer system. The compressor will be built at a laboratory scale, scaled up and commercialized after the initial development.

Nano-Catalyst

Nano-Catalyst

The overall objective is to develop durable, highly active electrocatalysts for the oxygen reduction reactions through a unique, bottom-up, rational design and ultimately reach cost competitiveness with conventional automobile technologies. The project encompasses new catalyst development and characterization active site modeling and membrane electrode assembly optimization and fuel cell testing. The project will culminate in internal and independent fuel cell tests demonstrating the capability of the novel catalyst materials of achieving the Department of Energy targets and advancing the state-of-the-art.

Hybrid Sulfur Process Technologies

Hybrid Sulfur Process Technologies

The project proposes the development and test of a new catalytic material to decompose sulfuric acid at the operating conditions required by sulfur-based thermochemical hydrogen production plants. The new material will be synthesized using very small particles of a high surface free energy core metal with a catalytically‐active outer metal shell deposited by electrodeposition. The new formulation will permit the increase of activity and limitation of catalyst deactivation. The catalyst will be tested in a lab scale reactor built at the Greenway Energy laboratories. A new solar reactor configuration will also be designed and fabricated, allowing for higher efficiency and reduced costs. The reactor will be on-sun tested at the solar facilities available at the National Renewable Energy Laboratory.